After many (many, many) trial-and-error attempts at printing the 5mm calibration cube step model from thingiverse (http://www.thingiverse.com/thing:24238), it looks like there really are some settings that are getting close to the ideal for the Printrbot Jr.

I owe a huge thank you to the Thames Valley RepRap User Group (https://plus.google.com/u/0/communities/107802060307152826013) for suggesting using frosted acrylic sheet as a print bed material. This stuff is awesome compared to everything else I tried: the default wooden bed, glass, and blue masking tape.

It was also nice to discover that other 3D printing newcomers had been suffering from similar pitfalls too – so suddenly I didn’t feel so stupid.

Anyway, here’s a snap of the last attempt – I reckon it’s somewhere between 80-90% successful. Today’s efforts start back left (#1), back center (#2) and so on to the front one (#7):

I’ve stashed the last-used settings file here: http://blog.justin.pnnr.net/printrbotjr-slic3r-config-ini/

A brief rundown of what changed within the settings file;

- Re-calibrated the Z and E motors very slightly. Your experience may vary with your machine but the technique described in the getting started guide for calibrating the E (extruder) seemed to work equally well for Z.

- Settled on a temperature of 185 degrees for this particular filament (Haberdashery Arctic White PLA 3mm). Along the way I also tried 180 – 200 degrees (in 5 degree increments) with pretty chaotic effects as you may imagine.

- The default speeds were too high, especially for small perimeters, so the top layers of cubes lost their definition and (as you can see in the photo) ended up looking very blobby. I generally passed through the slic3r config ini file and chopped all speeds by 50%. I may still have to slow down the small perimeter speed a little more to see if I can reduce the rounding on the topmost cube.

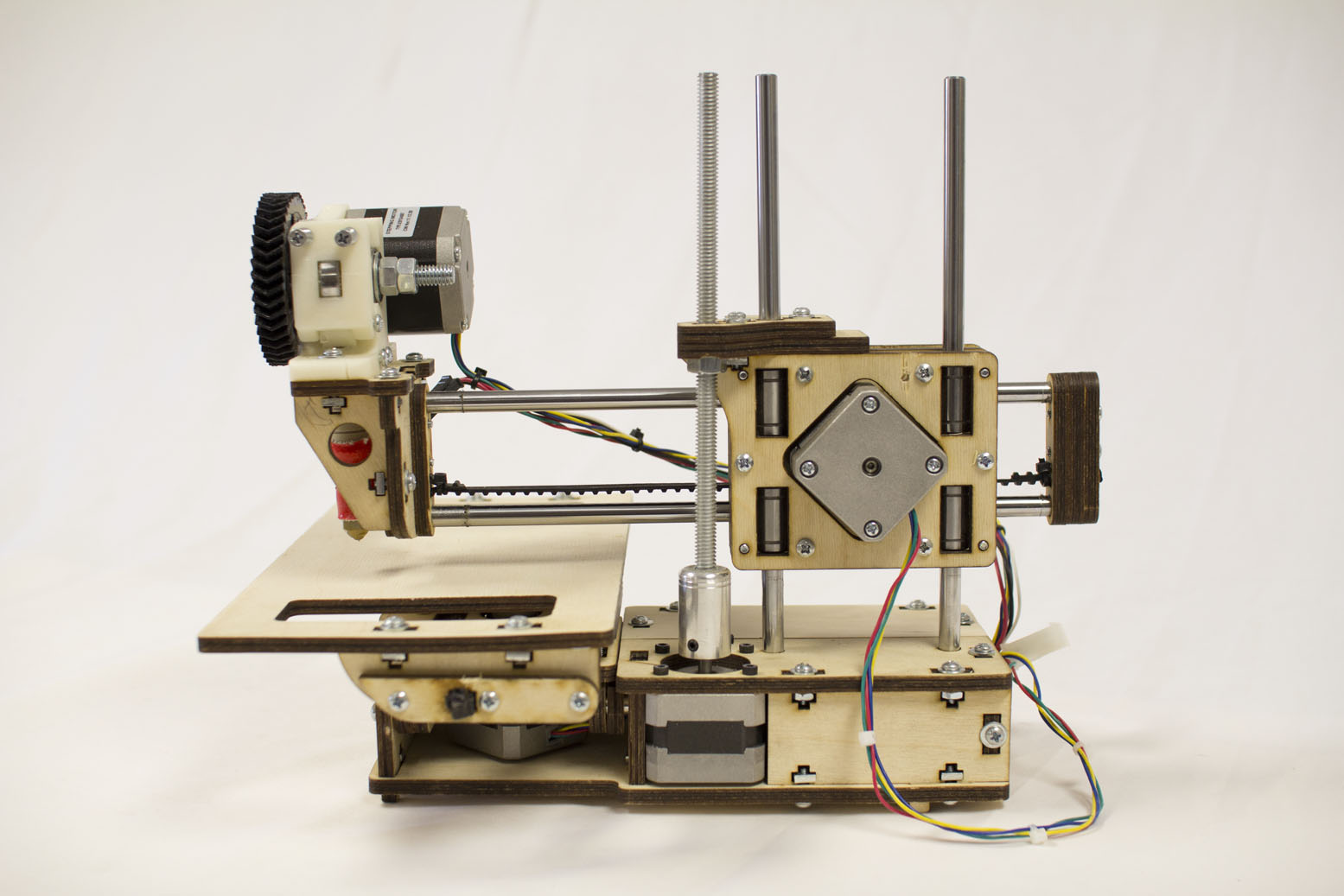

And for your further entertainment, here are a few other things we’ve printed over the last few weeks:

I think I may have another go at the bunny now that the printer is working so much more nicely now. Although I’ll make it smaller because this one lost the top of his/her ears 🙁 – no that’s not just bad photography!

The grey material was hopeless for printing anything with a small footprint. Could have been that the Jr’s bed needed de-greasing or something, or the material’s properties were just beyond the bounds of the settings I had tried.

The clear material supplied with the printrbot jr. was initially pretty good but it was difficult to see any detail in the printed objects. Again, this is more likely to be unsuitable settings than a problem with the filament though.

So after a challenging few weeks (here and there, not constantly) tweaking and retrying and getting wildly varying results it now feels like this little printer is beginning to settle into its stride.

Yay for the Printrbot Jr! (and thanks again to TVRRUG – you may have saved my sanity!)